how do rivets work diagram

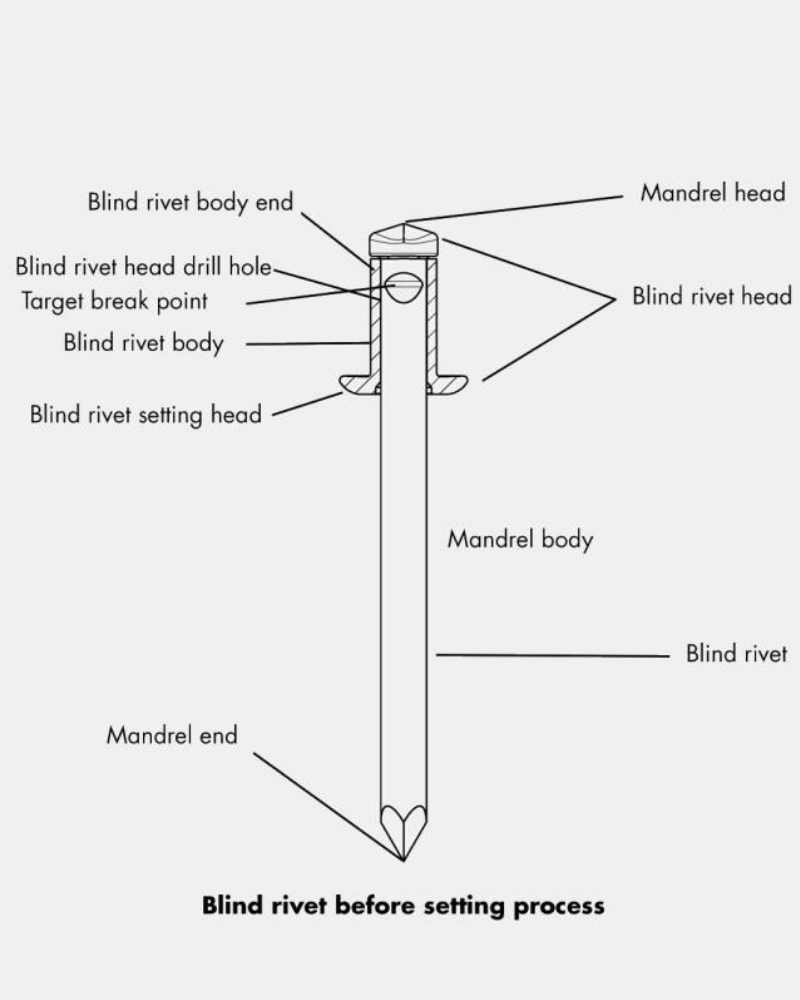

During blind riveting the nail is positioned in a blind rivet tool. A rivet is a permanent mechanical fastener with head-on at one end and a cylindrical stem called a tail at the other that has the appearance of a metal pin.

10mm 96mm 196mm.

. Once gripped the mandrel snaps permanently holding the rivet in place. Blind Rivet diameter 48mm x 2 96mm. The sleeve of the nail is inserted through one side of a hole after which the pin is pulled.

Some types of tubular rivets include compression full tubular and semitubular. Rivets with this kind of heads are used most of all. Slide the rivet through the two holes.

2 What is rivet riveting process definition meaning Image. A straight metal piece will be inserted via the hole or cavity provided for. How do Rivets Work.

The head is of a semi-circle in shape. Rivets come in 132. The two pieces of plastic or aluminium are drilled to a size slightly larger than the rivet.

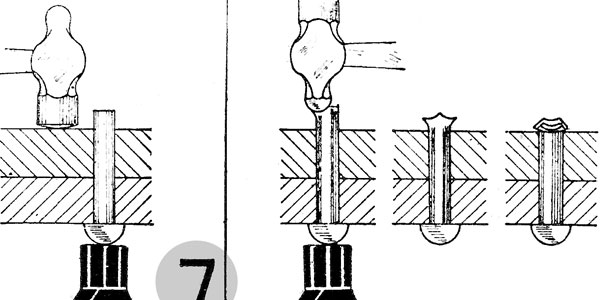

Before being installed rivets consist of a smooth cylindrical shaft with a head at one end. 1Put single rivet to locked hole component the core of the riveter is inserted into nail gun head. A permanently formed head at each end prevents the rivet from removal from the hole.

How does a Rivnut work. Remember from the diagram above the rivet is to act like a clamp we do not need or want to expand the body size of the rivet at all. How Do Blind Rivets Work.

Once it meets the face of the joins blind side the mandrel snaps causing the stem to eject to create a tight joint. A pop rivet can be used as a replacement for nuts and bolts screws welds and adhesives. Whether the installation tool is manual pneumatic or hydraulic the key factors to successful riveting depends on the quality of rivet the hole drilled and the force of the tool.

Adjust the air regulator to help drive the rivet in some seconds. The connection is created by the pulling motion which causes the sleeve of the blind rivet to roll up. Drill out the center of the rivet carefully.

Depending on the type of rivet and its ability to support shear load. A rivet is a permanent mechanical fastenerBefore being installed a rivet consists of a smooth cylindrical shaft with a head on one end. Follow up with a punch and a hammer.

As this happens the pin head is pulled into the rivet and the end of the. Snap head or cup head rivets. Rivets are non-threaded fasteners typically made of steel or aluminum.

The rivets are kind of the adjacent surfaces between the two parts to be joined. 2Pull riveting operation until the rivet is expanded back and the core is broken. Select a drill bit that is smaller than the hole which your rivet is positioned in.

A pop rivet is then inserted through the drilled hole and the rivet body is brought into contact with the parts. Learn to use the gun with one. A special pop rivet gun or tool pulls the mandrel head into the body of the rivet which then expands against the blind side of the join.

When installed the rivet is either drilled placed or punched into a hole afterwards the tail is then deformed holding the rivet in place. This will ensure that it doesnt remove any unnecessary material from your work pieces. In addition the aluminum and steel rivets can be supplied in all RAL colors.

The design of the hole helps to reduce the force required when rolling the tubular outward. A pop rivet gun is placed on the rivet pulling the mandrel into the rivet body causing it to expand and grip the parts to be joined. Thou shalt use the correct length rivet for the job.

Blind rivets are used to join two components together by driving the fasteners through previously drilled holes of the adjoining surfaces. Material thickness 10mm. The rivet pliers are pushed on to the pin of the rivet and the handles are pulled together.

Try to hold the gun as close to perpendicular as possible. That is why it is widely used in bridges made of iron material. Its diameter is 16D and its height is 07D.

Here are the most common 11 types of rivets-. If you do a lot of work on machines you are going to wind up having a variety of rivet lengths on hand to pick from. Choose a rivet length of 1821mm.

This type of rivets is shown in the figure. A permanently formed head at each end prevents the rivet from being removed from the hole. Before being installed a rivet consists of a smooth cylindrical shaft with a head on one end.

Exert body weight for holding firmly the gun against the rivet and the work-piece. When calculating the suitable length of a Peeled rivet take the total thickness of materials to be fastened and add on double the rivets diameter. The joints of this rivet are very strong.

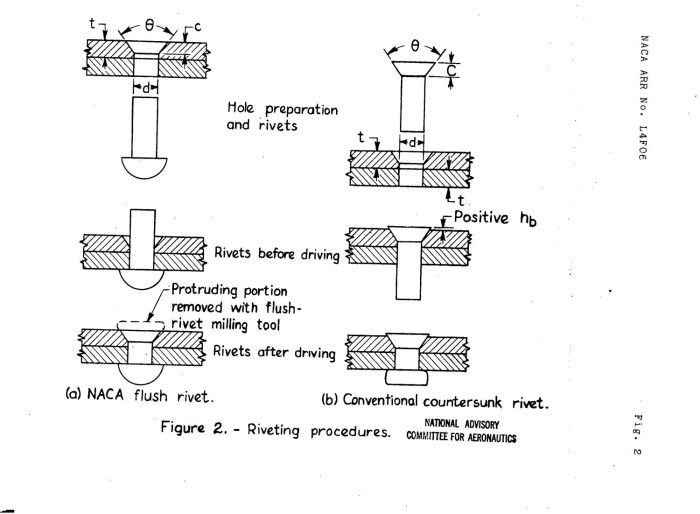

A rivet is a mechanical fastener with a plane unthreaded shaft thats inserted through holes to join two or more parts together. Gun head rivet tight top rivet face. Construction of aluminum air-frames process is explained by smoothing the wing surface to reduce aerodynamic drag increasing performance and efficiency in f.

Just in simple words the parts used to join together with the help of the rivet is known as the riveting process. The end opposite to the head is called the tailOn installation the rivet is placed in a punched or drilled hole and the tail is upset or bucked ie deformed so that it expands to about 15 times the original shaft diameter holding the rivet in. Common applications of the tubular rivet are ladders ducting systems lighting binders electronics mechanical product etc.

The shaft prevents any radial movements of the components. The pop rivet is passed through both holes in the sheet plastic aluminium. A rivet is a mechanical fastener with a plane unthreaded shaft thats inserted through holes to join two or more parts together.

The shaft prevents any radial movements of the components. Rivets with this kind of heads are used most of all.

What Is Rivet Definition Types Working Process Engineering Choice

What Are Structural Rivets Albany County Fasteners

Schematic Diagram Of Friction Self Piercing Riveting Process A Rivet Download Scientific Diagram

The Schematic Diagram Of The Riveting Process For The Countersunk Rivet Download Scientific Diagram

What Are The Types Of Rivet Heads According To The Indian Standards Machine Design Engineering Design Rivet

Structural Fasteners Solid Shank Rivets Installation Of Rivets

Illustration Of The Friction Stir Blind Riveting Process A The Download Scientific Diagram

Rivets Plan Download Free Vintage Model Aircraft Plan Model Airplanes How To Plan Model Planes

Usually Rivets From 3 16 Diameter Through 1 2 Are Easy To Obtain In Commonly Useful Lengths Custom Rivets Fo Blacksmithing Sheet Metal Tools Forging Tools

Blind Rivets Solid Rivets Rivets Metal Crafts Solid

Riveted Joints Definition Applications Operations Types Studentlesson

About Making And The Use Of Rivets Small Farmer S Journal

4 Tips For Stronger Blind Rivet Joints Machine Design Machine Design Blinds Joint

What Is A Blind Pop Rivet Gesipa

Methods Of Riveting And Material Used For Rivets Extrudesign Machine Design Riveting Rivets